Thousands of FIT OCEAN boards and all perfectly constructed. Call us a little bit crazy but we still do inspect every single board by hand. And besides, it is great to meet the folks in the factories personally, discuss new technologies and ofcourse thank them for their work.

The FIT OCEAN boards for 2018 look astonishing, the colors came out spectacular and it was extremely hard to find any errors during this check, except for some pencil marking to erase or polishing. We look forward to selling these boards next year and knowing the quality is that good we will have an easy year.

All iSUP’s in the world are being produced in China. The FIT OCEAN’s in one the most renown factories in the industrie with highly skilled workers.

Clockwise

1) Found a little marking during inspection to polish off. It reads ’30’ which is a code for the worker who made the board

2) We asked to meet who this is and where introduced to Mr. Zho

3) Checked!

4) All board get pumped up to 15 PSI and left 72 hrs. Afterwards we measure again to check

Clockwise

1) Thousands of FIT OCEAN Magic Glide 10’8 all perfectly made with CAD software and 3D printing

2) Diamond groove EVA brushed deckpad for optimal grip and soft for your skin. D-rings for a kayak seat

3) Neopren padded handle

4) New for 2018, the FIT OCEAN Cruise in Green

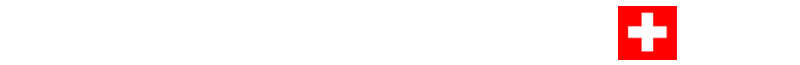

Clockwise

1) Boards need to have a 100% perfect straight flat bottom

2) The FIT OCEAN Windglide in orange

3) With an extra hard plastic disk under the EVA deckpad to carry the load of the sail

4) Polishing off some spots found during inspection